In the shift towards sustainable mobility, the automotive industry faces a complex challenge: vehicles must become lighter to reduce emissions, safer to protect occupants, and more sustainable to reduce their environmental footprint. Achieving this balance requires advances not only in materials, but also in manufacturing processes, structural design, and digital simulation.

Sup3rForm, Safe&Clean and FlexCrash three European projects coordinated by Eurecat, are contributing to this transformation by developing innovative solutions that combine lightweight design, crash performance and sustainability. Together, these projects are helping to shape the next generation of vehicle structures that will define the future of mobility in Europe.

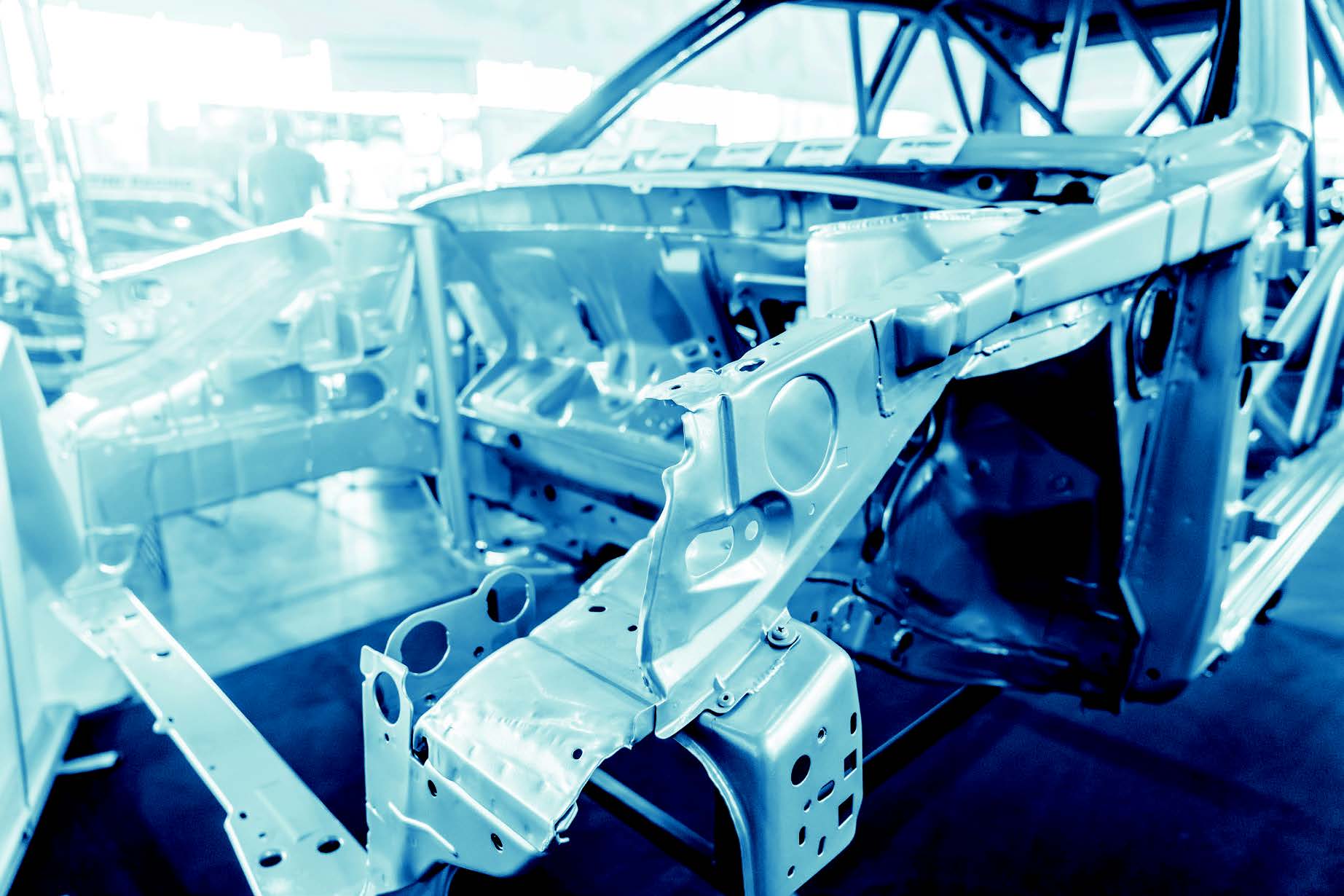

Balancing lightness and safety

Reducing vehicle weight has long been one of the most effective ways to lower CO₂ emissions and improve energy efficiency. Yet lighter structures must continue to provide high levels of crash protection. Meeting both goals, lightweighting and crash safety, demands a new generation of materials and processes, supported by advanced simulation tools. This is precisely where FlexCrash, Sup3rForm and Safe&Clean converge.

Adaptive aluminium crash structures

At the core of FlexCrash project lies the development of flexible and hybrid manufacturing technologies to produce adaptive crash-tolerant structures from green aluminium alloys.

By combining advanced manufacturing processes such as extrusion, HPDC (High-Pressure Die Casting), and additive manufacturing with cutting-edge digital simulation, FlexCrash aims to optimise crash performance while reducing both weight and environmental impact.

The project demonstrates that sustainability, safety, and innovation can coexist, showing how aluminium structures equipped with active systems can meet the stringent demands of modern vehicle design while supporting Europe’s climate goals.

Advanced steels for next-generation vehicles

The Sup3rForm project focuses on third-generation steels, including quenching and partitioning (Q&P) and medium-manganese grades, that combine high strength and ductility for improved crash resistance. These materials enable up to 20% weight reduction compared to conventional steels. Through detailed analysis of microstructures, fracture behaviour, and fatigue, Sup3rForm seeks to deliver advanced, industry-ready steels that support vehicle lightweighting without compromising safety.

These innovative steels enable up to 20% weight reduction compared to conventional grades, without compromising safety. Through detailed studies of microstructure, fracture behaviour, and fatigue, in combination with advance multi-scale modelling tools, Sup3rForm is delivering industry-ready steel solutions that support vehicle lightweighting while maintaining the highest safety standards.

Decarbonising safety-critical steel parts

The Safe&Clean project explores how low-carbon, high-recycled-content steels can be used safely in automotive safety-critical components such as door reinforcements and suspension arms.

By analysing the effect of impurities on crash and fatigue performance, and by developing predictive simulation tools, Safe&Clean ensures that increasing recyclability does not compromise safety and structural integrity. The project demonstrates that sustainability and safety can advance hand in hand, even in the most demanding automotive applications.

A shared vision for the vehicles of tomorrow

Together, FlexCrash, Sup3rForm, and Safe&Clean, all coordinated by Eurecat Technology Centre, embody Europe’s collaborative approach to sustainable automotive innovation. Their combined efforts illustrate that safety and sustainability can align, as lightweight, low-carbon materials continue to deliver robust crash protection.

They also show how digital simulation is transforming vehicle development by enhancing safety assessment and reducing time-to-market, while the use of circular and recycled materials builds confidence in the environmental performance of future vehicles.

Ultimately, these projects highlight that collaboration drives innovation, strengthening Europe’s leadership in the development of safer, lighter, and cleaner vehicle technologies. By advancing lightweight materials, adaptive structures, and virtual crash testing, the FlexCrash consortium is helping shape the foundation of tomorrow’s vehicles ones that are not only lighter and stronger, but also cleaner and more sustainable.