Safe&Clean in a nutshell

Understanding the safety performance of high-recycled content steels with low carbon footprint for critical automotive safety components

ABOUT THE PROJECT

The Safe&Clean project focuses on demonstrating that low-CO2 steels with high recycled content can safely meet the stringent requirements of modern automotive safety components.

Steel remains the most widely used material in cars due to its balance of strength, durability, and environmental efficiency. However, adapting low-emission steels at industrial scale requires understanding its behaviour under critical conditions: crashes, long-term fatigue, and post-assembly performance.

The Safe&Clean addresses these challenges by analysing two industrial use cases and evaluating how cleaner and sustainable steels perform in high-responsibility automotive parts. The project will analyse the influence of impurities present on steel grades processed by low-CO2 production routes on critical aspects related to steel manufacturability and safety performance. Special focus will be put on key safety factors such as crash performance, fatigue behaviour, weldability, and structural integrity of assembled components. Additionally, Safe&Clean will provide efficient testing methodologies to accelerate the validation and acceptance of scrap-based high-performance steels for automotive applications.

The project aims at generating reliable data to increase industry confidence on low CO2 steels, facilitating broader adoption of these sustainable materials in the automotive sector. It also contributes to EU goals for reducing greenhouse gas emissions, promoting resource-efficient production, and supporting the Clean Steel Partnership and the European Green Deal for a climate-neutral industry by 2050.

Key Data

EXPECTED RESULTS

The Safe&Clean project aims to deliver impactful outcomes through advanced research and innovation, generating results that support a more sustainable future for the steel and automotive industries.

Obtain representative examples of steels used in the automotive industry produced by low CO2 routes

Determine the effect of recycling on crash and fatigue performance.

Understand residual elements' role in steel manufacturability (cutting, formability and weldability).

Establish fast and cost-efficient characterization methods for market uptake of low CO2 steel products.

Demonstrate Finite Element Modelling (FEM) techniques for evaluating recycled steel in safety applications.

Showcase the project findings in two representative use cases, including material performance, accuracy of modelling and evaluation of Life Cycle Analysis (LCA).

OUR METHODOLOGY

The project evaluates the safety of clean steel solutions through two real-world use cases, assessing their industrial feasibility. This evaluation is built on three key pillars:

- Crash behaviour: high strain rate phenomena, fracture mechanics, advanced modelling.

- Fatigue performance: effect of residuals, influence of edge quality on fatigue behaviour, advanced modelling techniques.

- Structural integrity: welding, manufacturing, fatigue behaviour of weld joints, sub-system crash testing.

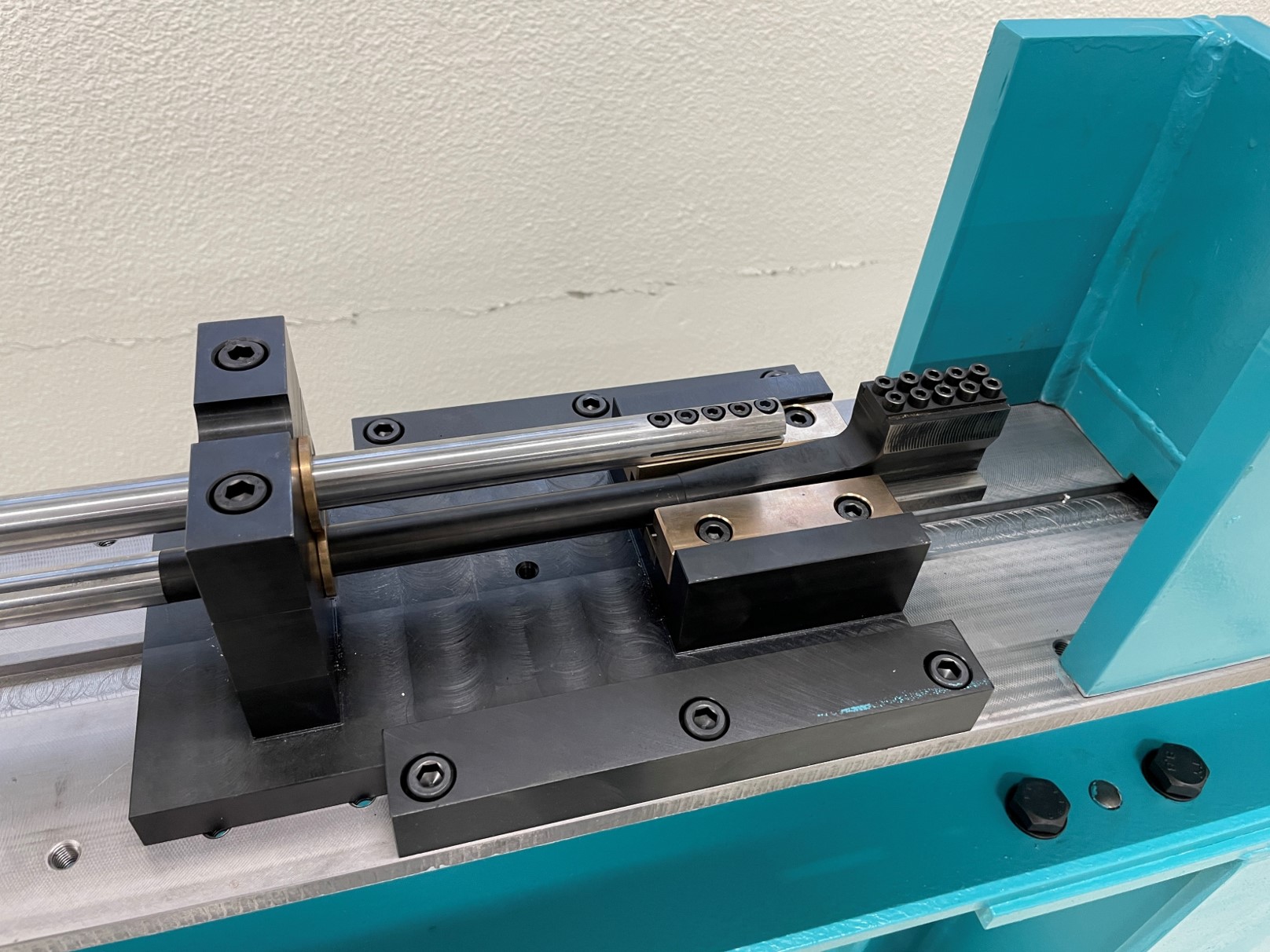

In the Safe&Clean, two automotive components are being developed using innovative steel grades: a door still and a lower control arm. These parts, designed for crash safety and structural performance, will be manufactured with both high and low residual steel content.

Advanced simulations and real-world testing will assess formability, strength, corrosion resistance, and overall quality, comparing results to current industry standards. This ensures that sustainable steel solutions meet industrial performance and safety requirements.

PROGRESS BEYOND THE STATE OF THE ART

Low CO2 sheet steel for automotive applications

State of the art: Most automotive steels use high-emission blast furnace methods. Low-CO2 processes introduce impurities from scrap, risking performance.

Safe&Clean contribution: Developing two low-CO2 steel grades for car bodies and chassis, studying impurities’ effects to enable wider adoption.

Finite Element Modelling as a tool for evaluating the safety performance of recycled steel

State of the art: Existing simulation models for crash and fatigue are accurate for conventional steels but fail to account for property variations in recycled, low-CO₂ steels.

Safe&Clean contribution: Developing advanced material models that integrate the effects of impurities, enabling accurate simulations of recycled steels.

Spot Welding and Arc Welding for sheet steel with residual element contents

State of the art: Spot and arc welding are essential in automotive production, but residual elements in recycled steel can affect weld quality and reliability, creating uncertainty in structural performance and crash safety.

Safe&Clean contribution: Evaluating how impurities impact weld strength and consistency in low-CO2 steels, while improving welding simulation models to predict weld quality more accurately for these sustainable materials.

Determining how residual elements affect fatigue life on steel components

State of the art: Fatigue life is crucial for parts like chassis that face repeated stresses, yet the impact of residual elements from recycled steel on fatigue behaviour is poorly understood. Furthermore, manufacturing processes like shearing can worsen fatigue performance, making the use of low-CO₂ steels more complex.

Safe&Clean contribution: Developing a systematic approach to evaluate how impurities and edge cutting affect fatigue life. A rapid fatigue testing method will also be introduced to speed up material assessment.

Crash performance studies of sheet steel and the influence of residual elements

State of the art: Assessing crash resistance is costly, complex, and sensitive to. Research on how impurities affect crash performance, especially under high strain rates, is extremely limited..

Safe&Clean contribution: the project is the first one to study how residual elements impact crash safety in high-strength steels. The project will also develop faster, more efficient crash testing methods to speed up adoption of low-CO2 steels in automotive applications.

Determining the environmental gains of low CO2 steel solutions:

State of the art: Achieving EU climate goals requires decarbonizing industries like steel, which could cut emissions by up to 80% with new production methods. However, current carbon footprint estimates for clean steels lack real-world, component-level validation.

Safe&Clean contribution: Performing life cycle assessments (LCA) on two automotive components made with low-CO₂ steel, providing practical data to support EU carbon neutrality strategies.

CONSORTIUM

The project, coordinated by Eurecat Technology Centre of Catalonia, is participated by nine entities, including actors from the steel industry, the automotive safety sector and research organisations: Autotech Engineering Deutschland, Centro Ricerche Fiat, I2M, IDIADA, Istituto Italiano della Saldatura (IIS), the University of Mondragon, SSAB, Salzgitter AG and the University of Siegen.

Eurecat is the leading Technology Centre of Catalonia, providing the industrial and business sector with differential technology and advanced expertise.

The centre offers solutions to their innovation needs and boosts their competitiveness in a fast-paced environment. It brings together the expertise of 650 professionals who generate a volume of income of 50M€ per year. Serving more than a thousand companies, Eurecat is involved in 200 projects of R&D national and international with high strategic value.

Contribution to Safe&Clean

Eurecat, through its Unit of Metallic and Ceramic Materials, is responsible for project management, coordination, and dissemination. With extensive experience in participating in and coordinating international research projects in steel sector, Eurecat (EUT) will lead and contribute to the metallurgy studies, fractographic analysis, mechanical characterization, as well as fracture and formability characterization. Additionally, Eurecat will oversee the Communication and Dissemination strategy via its Research Communication Office.

![]()

![]()

Contribution to Safe&Clean

As part of this project, IIS, recognized experts in the design, construction, and testing of welded joints, will: support the analysis of requirements and specifications for end-user case studies; verify the design compliance of welded joints in the produced samples; identify critical issues for investigation in the Fitness-for-Service (FFS) assessment of the samples’ serviceability; and validate results from NDT and laboratory tests with reference to the welded joints.

Gestamp has led the automotive components industry for over 25 years, driven by innovation, technology, and a pioneering spirit. Gestamp is a multinational specialized in designing, developing, and manufacturing high-engineering components that contribute to making vehicles safer, lighter, and more sustainable. Its products cover the areas of BiW, Chassis and Mechanism.

With a presence in 24 countries, 115 production plants, and a workforce of over 43,000 employees, it pushes boundaries through geographical diversification, technological expertise, and operational excellence.

Through an international network of 13 R&D centers, we innovate to offer groundbreaking solutions that make a difference in mobility of the future.

Contribution to Safe&Clean

Autotech Engineering Deutschland GmbH, as part of Gestamp, will contribute to the project by assessing the performance of low CO2 steels under demanding conditions relevant to automotive applications. As steel remains the most widely used material in passenger cars, and its adoption is expected to increase due to its excellent balance between performance and CO2 footprint, Gestamp will focus on evaluating how low CO2 steel grades influence critical safety aspects and influences on manufacturing. This includes detailed studies on fatigue and crash performance, design and structural integrity, ensuring that the deployment of these steels at industrial scale does not compromise safety requirements.

With its strong expertise in automotive engineering and advanced forming processes, Gestamp will provide key insights to bridge the gap between material development and real vehicle applications.

![]()

![]()

Contribution to Safe&Clean

Our success in product development is built on a unique blend of highly experienced engineers, state-of-the-art test and development facilities, and the constant drive towards innovation. The company has +3,400 professionals and an international network of 61 subsidiaries and branch offices in 24 countries, ensuring our clients receive fast, customized solutions.

Contribution to Safe&Clean

IDIADA serves as the key testing and validation partner, specializing in crash testing and safety assessment of car’s structural components. Their main responsibilities include conducting physical crash tests at the subsystem level, developing crashworthiness analysis to support computer simulations, and validating the performance of sustainable steel components in real collision scenarios. Specifically, IDIADA will design and execute subsystem crash tests (particularly for components like front suspension lower control arms and car sill), perform component testing according to defined configurations, and provide advisory support for dynamic crash behavior modeling. Their work is crucial for ensuring that low CO2 steels meet automotive safety standards before market implementation.

![]()

Mondragon Unibertsitatea combines training, research, and knowledge transfer to improve the competitive position of companies and organisations. More than half of the university’s research funds come from private contracts, and it is ranked among the top European universities in knowledge transfer according to U-Multirank.

Contribution to Safe&Clean

Mondragon Unibertsitatea’s role in this project focuses primarily on the quasi-static and dynamic characterization of the materials, assessing their plasticity, fracture, and fatigue behaviour. In addition, it supports the development and calibration of material models using the experimental data obtained from these characterizations. Finally, Mondragon Unibertsitatea contributes to the formability analysis of the materials involved in the project, with special attention to their cutting behaviour.

![]()

Contribution to Safe&Clean

USIEGEN primarily focuses on the characterization and modelling of the dynamic mechanical properties of automotive sheet metals. A comprehensive experimental program on material testing will be carried out at USIEGEN, addressing the effects of strain rate, temperature, and stress state on plasticity, damage, and fracture behaviour. In addition, crash simulations will be performed using advanced user-defined plasticity and damage mechanics models.

![]()

![]()

SSAB is a global steel company with a leading position in high-strength steels and related services. SSAB is revolutionizing steelmaking with two unique decarbonized steels and aims to largely eliminate carbon dioxide emissions from our own operations.

SSAB Europe is responsible for sales of strip, heavy plate and tubular products in Europe, the global business in the Automotive customer segment (AHSS) and for steel and plate production. SSAB has a strong global presence with employees in over 50 countries and a production capacity of approximately 8.8 million tonnes.

Contribution to Safe&Clean

SSAB will provide four hot rolled steels, all HR550LA, for the project. One scrap based, one conventional steel produced in a blast furnace for reference and two BF steels with different levels of Cu and Sn added.

Contribution to Safe&Clean

In the Safe&Clean project, i2m evaluates the environmental impact of the Safe&Clean materials and processes. This analysis quantifies energy use, emissions, and resource efficiency to demonstrate the sustainability benefits of the high-recycled-content steel solutions.

NEWS & EVENTS

European consortium to study the viability of sustainable steels in automotive safety components

The European Safe&Clean project, coordinated by the Eurecat technology centre, aims to demonstrate the viability of sustainable steels, with low CO₂ emissions and high recycled material content, to meet the stringent quality requirements for manufacturing modern automotive safety components. “Steel is a key material in vehicle manufacturing, offering an [...]

Eurecat showcases sustainable steel innovations at SteelTech Congress 2025

Eurecat has participated as exhibitor at the Steel Tech 2025, held at the Bilbao Exhibition Centre from October 21 – 23. At the event, Eurecat highlighted its technological capabilities in the steel sector, presenting information on several EU-funded projects including CiSMA, COOPHS, Safe&Clean, SuPreAM, Sup3rForm, NewAIMS, HELIX, DURALINK, Steel4Fatigue, [...]

Eurecat presents results on the effect of hydrogen on the mechanical properties of high-strength steels at the Steel & Hydrogen Conference

Eurecat took part in the Steel & Hydrogen Conference (the 5th International Conference on Metals and Hydrogen), held from 14 to 16 October in Ghent, Belgium, organised by OCAS and Ghent University. At the conference, Amadeu Concustell and Silvia Molas from the Metallic and Ceramic Materials Unit at Eurecat, [...]

Safe&Clean poster presented at ESTAD Conference in Verona

The Safe&Clean project was showcased at the 7th European Steel Technology and Application Days (ESTAD) Conference, held from 6th to 9th October in Verona, Italy. Stefano Bucci, project partner from Centro Ricerche Fiat, presented the poster titled “Decarbonization of Steel: Challenges and Opportunities for Modern Steelmakers and Carmakers”, which [...]

Safe&Clean project kicks off to show sustainable steels can deliver on automotive safety

The Safe&Clean project has kicked off. Project partners have met in Manresa (Spain) on July 29th 2025, aiming to demonstrate that CO2 steel with high recycled content can safely meet the stringent requirements of modern automotive safety components. During the meeting, all partners presented their entity and an outline [...]

RESOURCES

Here is a list of Safe&Clean work packages and deliverables.

WP1 – Management, Dissemination and Exploitation

D1.1 – Comprehensive overview of the project

D1.2 – Risk assessment and contingency plan

D1.3 – Communication and dissemination plan

D1.4 – Public publishable report

WP2 – Use Case Definition

D2.1 – Use case definition

D2.2 – Environmental performance of the current solutions

WP3 – Sustainable Steelmaking

D3.1 – Analysis of Low CO2 steel

WP4 – Modelling Fatigue and Crash Performance

D4.1 – Setup of an accurate Crash FE model for low CO2 steel

D4.2 – Setup of an accurate fatigue FE model for low CO2 steel

WP5 – Safety Performance of Sustainable Steel

D5.1 – Safety performance of Low CO2 steels

WP6 – Implications of Sustainable Steel on Manufacturing

D6.1 – Manufacturing with Low CO2 steels

D6.2 – Cutting and border quality of Low CO2 steels

WP7 – Use Case Validation and LCA

D7.1 – Life Cycle assessment

D7.2 – Performance of low CO2 steels

CONTACT US

Contact: safeclean-project@eurecat.org