FormPlate seeks to optimise the energy efficiency, cost and durability of metallic bipolar plates, a key component to guarantee the energy efficiency of proton exchange membrane (PEM) hydrogen fuel cells for application in the automotive sector.

The technological innovation of the project is based on:

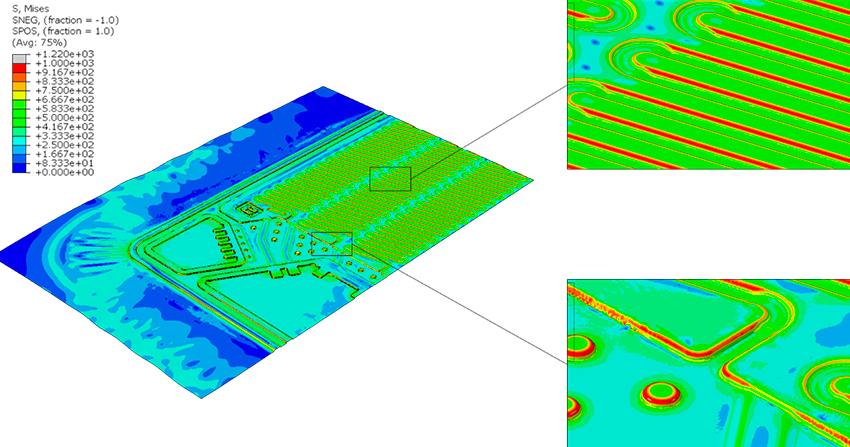

- New geometric plate designs by Finite Element Method (FEM) and Computational Fluid Dynamics (CFD) simulations.

- Development and improvement of plate manufacturing techniques.

- Implementation of alternative metallic materials to reduce the cost and weight of the plates.

- Development of protective, electrically conductive and corrosion-resistant coatings.

The energy transition towards electromobility and sustainability requires rapid and efficient technological reconversion from companies that manufacture components for vehicles with combustion engines to guarantee their survival and competitiveness in such a strategic sector for the Spanish economy.

Eurecat participates in the FormPlate project through its Metallic and Ceramic Materials Unit, the Product Innovation & Multiphysics Simulation Unit and the Chemical Technology Unit.

Apart from Eurecat, the project is participated by the company ESTAMP S.A.U.

General details

Project

FormPlate – Innovation in materials, design and manufacture of high-performance and durable PEM fuel cell bipolar plates

Project reference

CPP2021-008514

Programme and call for tender

Project funded by the Spanish Ministry of Science and Innovation through the call “R+D+i Projects in Public-Private Collaboration“, State Program to Promote Scientific and Technical Research and its Transfer, from the State Plan for Scientific, Technical Research and Innovation 2021-2023, within the framework of the Recovery, Transformation and Resilience Plan