Adaptive laser beam for additive manufacturing. The ALABAMA project develops and matures adaptive laser technologies for laser metal deposition (LMD) processes with either powder or wire as feedstock material. The objective is to decrease the porosity and to tailor the microstructure of the deposited material by shaping the laser beam, both [...]

H-LEAF

EurecatIG2024-03-19T11:27:36+01:00New technology for the generation of green hydrogen. The H-LEAF project develops a PEM (Proton Exchange Membrane) electrolyser based on a new national patented technology. H-LEAF focuses on the research of new scalable and sustainable components, coatings, materials and processes to overcome current limitations in the provision of materials for hydrogen [...]

ZEvRA

EurecatIG2024-03-08T11:40:53+01:00Zero emission electric vehicles enabled by harmonised circularity. The ZEvRA project improves the circularity of light-duty electric vehicles (EVs) throughout their entire value chain, from materials supply and manufacturing to end-of-life (EoL) processes. To do so, ZEvRA develops a Design for Circularity (DfC) methodology and a holistic circularity assessment aimed at [...]

SPAR3D

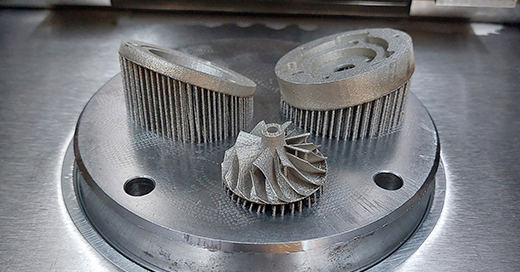

EurecatIG2024-02-05T15:50:31+01:00Research, study and demonstration of strategies to obtain profitable metal spare parts in additive manufacturing processes for the automotive industry. The SPAR3D project focuses on additive manufacturing (AM) or 3D printing, a disruptive technology that is increasingly used in the manufacturing and repair of metal parts. SPAR3D proposes an integrated process [...]

2E4GREEN

EurecatIG2024-04-03T11:51:21+02:00Development of new ester-based oils and additives, as well as lubrication strategies for electric mobility. The 2E4GREEN project boosts a smart-lubrication strategy based on the selective activation of microencapsulated additives to reduce friction and wear, increase lubricant efficiency and extend service life. It does so by taking into account both the [...]

EQUIDENTAL

EurecatIG2024-01-08T12:49:28+01:00Development of advanced surface treatment equipment for functional enhancement of dental implant components. The main objective of the EQUIDENTAL project is the development of low cost, simple, flexible and modular surface treatment equipment addressed to manufacturers of dental implants and surgical tools. The technological innovation of the project is based on: [...]

NewAIMS

EurecatIG2024-04-24T11:59:06+02:00NewAIMS in brief Conceptualization, study and demonstration of strategies to obtain cost-effective high-performance steel in metal 3D printing processes ABOUT THE PROJECT Additive Manufacturing (AM), and 3D Printing in particular, offer attractive possibilities for design optimization and production of [...]

SuPreAM

EurecatMV2024-04-26T15:55:40+02:00SuPreAM in a nutshell Boosting the implementation of Additive Manufacturing with optimal surface integrity ABOUT THE PROJECT The SuPreAM project is developing and improving the performance and capabilities of a predictive simulation model of finishing operations in steel Additive Manufacturing [...]

Sup3rForm

EurecatIG2024-04-19T07:04:46+02:00Sup3rForm at a quick glance Optimizing 3rd Generation Quenching and Partitioning (Q&P) and medium-Mn steels to attain improved in-use properties and foster their widespread deployment in the automotive industry ABOUT THE PROJECT Generating a comprehensive understanding on the relationship [...]

SENECA

EurecatIG2023-05-22T14:20:54+02:00Recovery of Critical Raw Materials, manufacturing of products with Secondary Raw Materials and traceability of their composition. The SENECA project, focused on the growing demand for mineral resources and strategic materials worldwide, investigates the potential of secondary sources of mining and industry through recovery and recovery processes of Critical Materials. The [...]